The cannabis community prides itself on quality craftsmanship and culture. It’s an admirable trait. But many are resisting modernization and tools like automation for fear of losing authenticity. I get it. No one wants the cannabis industry to lose its customs and historic flare. However, automation is not here to erase tradition. Rather, its job is to protect it and enhance the way we currently manufacture cannabis.

By reducing raw material loss, ensuring quality consistency, and improving operational efficiency, smart automation allows cannabis brands to scale without sacrificing the integrity of the plant or the values that built the industry.

The Hidden Costs of Manual Cannabis Production

Craft cannabis is often thought of as handmade, which definitely attracts customers looking for an authentic, classic product. But manual operations often result in product spillage (goodbye perfectly good flower, hello costs associated with product loss), overfilling or underfilling (especially in pre-rolls or jars), mislabeled or non-compliant packaging, and human fatigue and error.

All the above leads to increased labor and material loss costs which impacts a company’s bottom line. When only an average of 27.27% of U.S. cannabis businesses are profitable, the industry cannot afford substantial product loss.

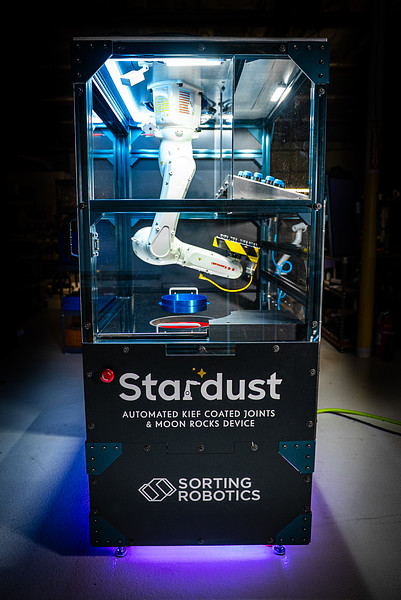

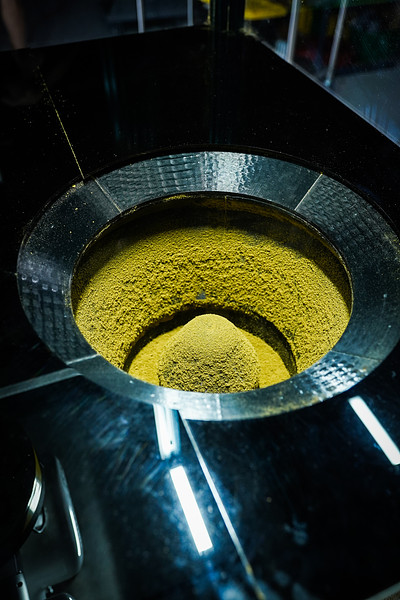

And let’s not forget about the labor challenges and risks associated with manual cannabis manufacturing. Take, for example, kief-coating pre-rolls. Typically, when people are manually rolling joints in kief, they do so on open tables. All the excess kief is then brushed off the tabletops and swept up from the floor. This becomes a breathing hazard when the fine dust of the kief is airborne.

So not only is manual processing of cannabis products slow, creating an operational bottleneck, but labor challenges create a hazardous work environment that can derail entire production lines for weeks.

Here’s where automation comes in to save the day (and your staff, and your business).

A Guardian of Quality and Consistency

What is smart automation?

Smart automation refers to the integration of advanced technologies such as artificial intelligence (AI), Internet of Things (IoT), robotics, and automated systems to optimize production processes. This approach enhances efficiency, consistency, and scalability while reducing labor costs, errors, and environmental impact.

To continue with the kief-coating example from before, an automated kief-coating system can enclose the process, capturing and containing any airborne materials while a machine coats the joints. First, your workforce is protected from exposure to potentially hazardous materials in the air. And second, your production output can increase, potentially by thousands.

Beyond reducing labor costs, smart automation delivers precise dosing and filling, tamper-proof compliance, and minimal product loss, enabling consistent, high-quality production at scale.

Also Read: The Rise of Functional Nutrition for Older Adults

Tradition Meets Innovation

Some operations literally have 500 people manually handling this process in massive warehouses about the size of a football field. There are tables for painting, stations for drying, and multiple steps that make the workflow inefficient. Even with a skilled worker doing five units per minute, which is considered fast, you’re still limited by how many people you can hire. Meanwhile, smart startups are using automation to produce up to 1,200 units per hour with just one operator.

Right now, the only way to scale manually is by adding more labor, which simply isn’t practical or sustainable. That’s why you’re going to see more businesses shift toward automation. Some will automate the entire process, from distillate application to kief coating, while others might introduce separate systems for each step. Either way, automation is clearly the direction the industry is heading.

At this point, innovation isn’t about what else we can pack into a joint since they’re already filled with everything imaginable. The next evolution is about how efficiently we can make them. In fact, a study by Velosio found that nearly half of cannabis operators believe the increasing use of automation and robotics for production will enhance operational efficiency.

Let me be clear: automation is designed to support, not replace, the human touch. Operators can integrate automation without losing artisanal credibility.

Take vape cart filling, for example. Instead of having someone manually squeeze distillate from a heated gun into each cartridge, which can lead to repetitive strain injuries like carpal tunnel, you can automate the process. Now, the operator simply loads bulk material into a system that handles volume precisely. Not only does this reduce physical strain, but it also eliminates contamination risks. Workers aren’t hovering over open cartridges, potentially breathing on them or, in less regulated environments, accidentally spitting into them. Automation helps ensure a clean, consistent fill while also removing exposure to airborne contaminants.

The same applies to flower handling. Instead of using open-air knockboxes that kick up dust and particles, automated systems often enclose the process, capturing airborne material and reducing respiratory hazards. With kief coating, too, automation allows operators to control the entire environment and minimize human contact and manage exposure to fine particles or volatile substances that could pose a risk to anyone nearby.

Ultimately, what automation enables is control: over environmental variables, over product consistency, and most importantly over human exposure to physical risk or contamination. That’s why it’s becoming foundational in modern cannabis production.