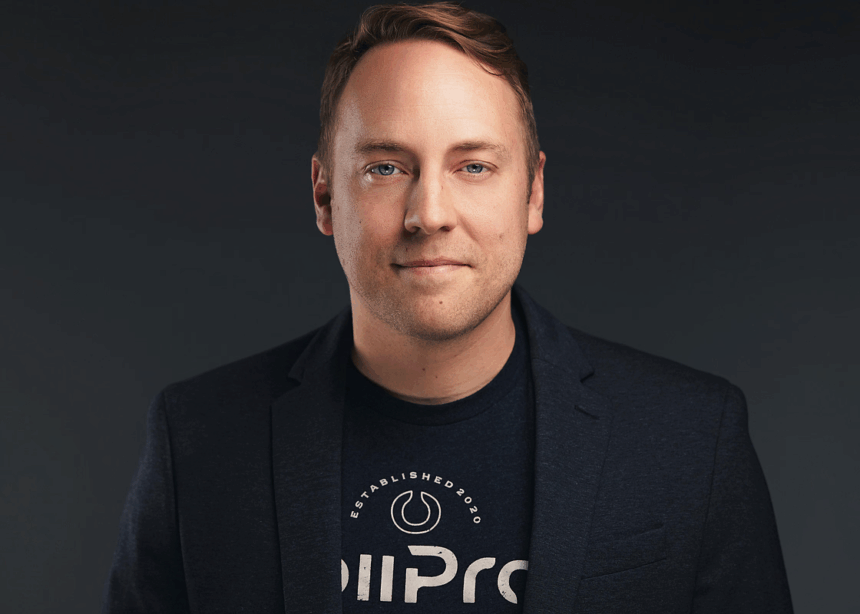

As the Founder and CEO of RollPros, Loucks brought his background in medical devices, optics engineering, and VR hardware to cannabis manufacturing, challenging the long-held assumption that pre-roll automation required pre-made cones or would result in inconsistent, low-grade products. The result of that challenge? The Blackbird.

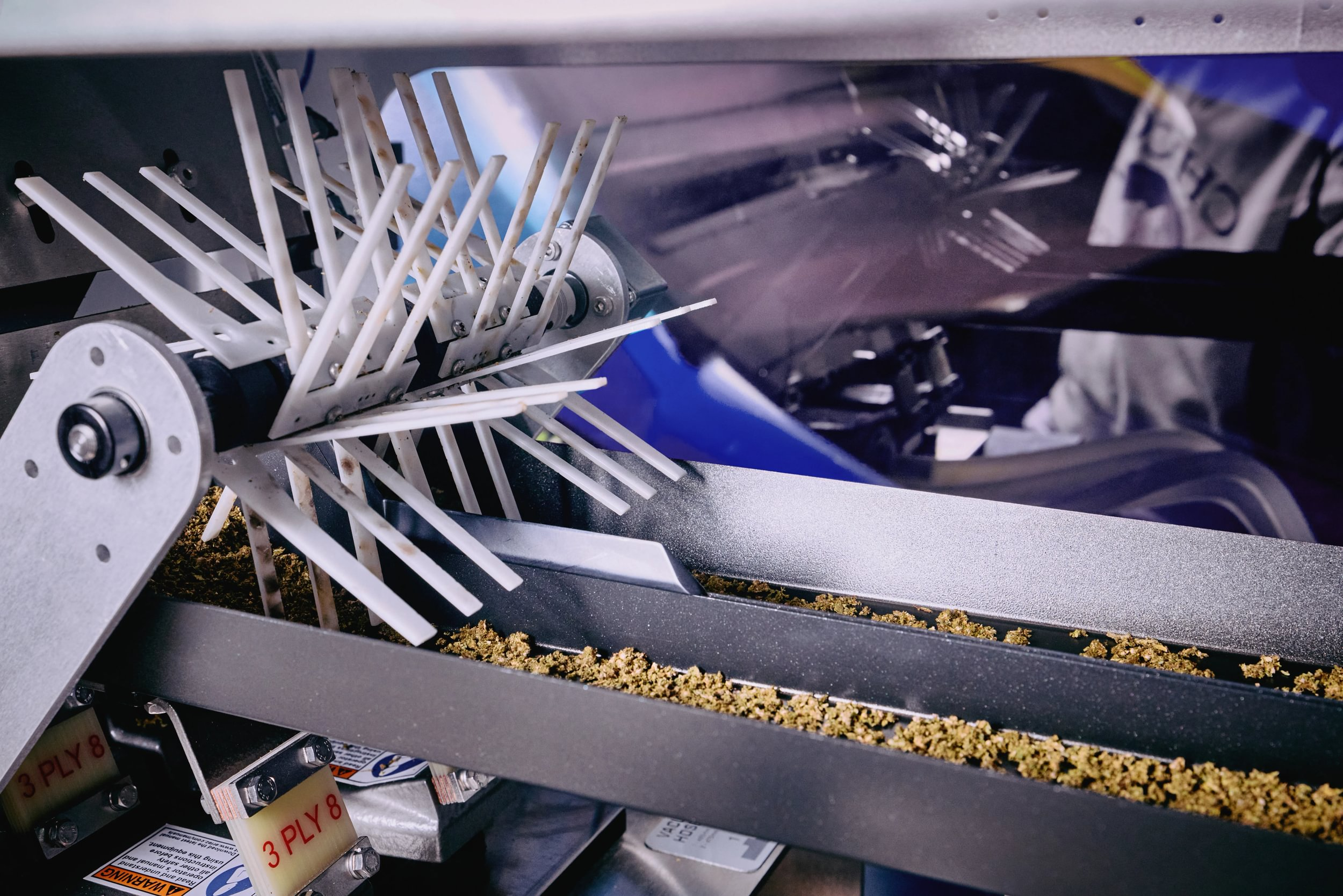

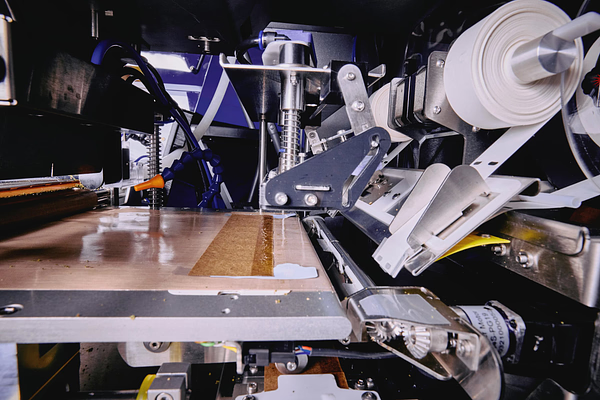

RollPros’ flagship system uses proprietary TruRoll technology to replicate the precision and craftsmanship of hand-rolled joints at scale. Unlike conventional systems that rely on vibration, funnels, and cones, the Blackbird radially compresses fresh ground flower into uniform joints that retain potency, aroma, and consumer appeal, while giving operators a more efficient and flexible production model.

In this interview, Loucks shares what inspired his leap from tech into cannabis, how automation can actually enhance product integrity, and why he believes the pre-roll is finally stepping into its golden age.

Cannabis & Tech Today: The cannabis pre-roll market has exploded in recent years, but quality remains a persistent challenge. What was the moment you realized this part of the supply chain was ripe for disruption?

Kyle Loucks: I saw it back in 2016 when I had my first stuffed cone. What a freaking whiff that was. I was downright outraged at the lack of quality or attention to my needs as a consumer. I know that makes me sound like a diva, and maybe I am, but it really did undermine my expectations. I felt betrayed by the brand that sold it to me.

From that moment, I joined the same camp as every other true joint roller: I would never buy another preroll. I’d just buy flower and roll my own. That sent me down the rabbit hole to figure out why the experience was so bad, and I kept finding problem after problem in how prerolls were made. First, it took a dozen people, with half of them literally weighing and twisting tops. Then I found out they were filling from the top, an obvious limitation for using sticky flower. And then I found out the cones themselves were hand made in sweat shops overseas, and I nearly jumped out of my seat. There was no way this model could sustain the needs of this industry.

C&T Today: RollPros is known for its TruRoll technology, which mimics the hand-roll process. Why was it so important to replicate that manual precision, and how did you engineer it into an automated system?

KL: Well it kind of stemmed from necessity. Anyone who has ground up freshly cured flower knows it can quickly turn into a sticky situation. And typically, the stickier the better! I knew I had to adapt to the flower rather than make the flower adapt to me. The best way to do that was to use the stickiness to my advantage, and that is exactly what rolling does. I started with the ol’ dollar bill trick to roll a joint, and then began layering on sensors, motors, and actuators to help achieve the ultimate goal: creating the perfect joint.

C&T Today: Pre-roll production has long relied on cones, but RollPros took a different path. What are the limitations of cone-based systems, and how does eliminating them change the game for producers?

KL: The cone was simply a means to an end. It was designed to be filled from the top, and that’s about it. It wasn’t designed for sticky flower. It wasn’t designed for good airflow. It wasn’t designed to be easy to fill. And it certainly wasn’t designed to be cost effective. Did I mention that all cones are still hand made overseas? Imagine a dimly lit warehouse with dozens or even hundreds of people hunched over benches twisting paper into cones.

There are many flaws, but the biggest one is this: to make cones work, you have to over-grind your flower and dry it out to make it properly fill a cone, and in that process you lose all the great attributes of the flower.

C&T Today: You’ve worked on everything from medical devices to Oculus VR hardware. How did your background in high-tech and human-centered design influence how you approached cannabis manufacturing?

KL: It’s funny, I brought a little from each product that I worked on. Things like remote firmware dispatch from Oculus or paper path engineering at HP. But really, they were stepping stones, proving to myself that I could have an impact on the world.

I was born critical, always questioning everything—especially myself. Pair that with rigid schooling and a sprinkle of dyslexia, and it was tough on my confidence. After college, I was set free from standards and truly “out there”.

At just 23, I helped reframe how implants were designed. We realized titanium could be plastically deformed to fit bones better, and that was my first real innovation. It validated my ability to impact the universe. From there, I helped deliver one of HP’s quietest printers, invented the cutlery dispenser you see at Costco, and even won a build competition at Meta with an AR headset that went directly to Zuck.

Cannabis was always my back pocket secret that helped me unlock new perspectives and solve hard problems. When legalization lined up with the end of my corporate career, I took it as a sign. That was some higher being telling me just what I needed to do.

C&T Today: Automation is often seen as a trade-off between efficiency and artistry. How do you balance engineering precision with the sensory experience that consumers associate with a well-rolled joint?

KL: In my opinion, this is the key difference between automation and innovation.

Automation takes a manual process and mechanizes it. That’s basically what all cone machines do, and unfortunately, all they’ve accomplished is making it possible to produce low-quality joints faster.

Innovation, on the other hand, deconstructs the larger issue. It asks: how is the end product experienced? How is the supply chain affected? How can this scale to millions of joints? These questions are difficult, which is why most people avoid them. True innovation is about finding the balance between each of these challenges to solve the problem fully.

It’s also important to point out that the Blackbird is a tool, and you need good inputs to produce high-quality joints with it. First and most important is high-quality flower. No amount of tech is going to turn garbage weed into a good joint! And second, you need a well-trained operator that knows what a quality joint looks, smells, tastes, burns and feels like. We consider Blackbird operators to be joint rolling artists. We’ve just given them a bigger, better paint brush!

C&T Today: As a product category, pre-rolls are evolving from “value” offerings to premium experiences. How do you see consumer expectations shaping pre-roll innovation over the next few years?

KL: As markets mature, so do consumers. They become more educated and critical in how they spend their money at the dispensary. If you have a low grade product priced the same as a high quality one, you will lose. We see this in every market, but it’s most obvious in the OG markets like California and Oregon. If you’re not already focused on quality, you’ll soon be left behind.

C&T Today: Beyond just rolling joints, RollPros is helping businesses reduce manual labor and reallocate human capital. What does this shift mean for scaling sustainably in a hyper-competitive market?

KL: This means you can focus more of your time and energy on running the business and generating recurring revenue through brand loyalty. It’s more about the consistency of the products that are rolling off the BlackBird that help the scalability of your business. If you’re still relying on the inconsistent nature of stuffing cones, you will eventually lose that customer base. It’s only a matter of time before they get a clogged or canoeing cone.

C&T Today: What are some of the most surprising or creative ways your customers have used the Blackbird system in their own workflows or product development?

KL: I love seeing what my customers are coming up with! One of my favorites is a customer in British Columbia who makes joints with a crutch at each end. You can cut it to length and choose how much you want to smoke. I am also a big fan of the people who are running glass or ceramic tips—my wife won’t smoke anything else!

C&T Today: For cannabis operators who are skeptical about investing in automation, what’s the one misconception you’d like to clear up?

KL: First, I’d say it’s good to be skeptical. It’s a big step in the growth of a business, and you should do as much due diligence as possible. Second, look at the people behind the company and their track record. At RollPros, we stand behind all of our customers and act as a long-term asset to their business. From packaging to helping develop marketing materials, we are here to support them. Third, you have to automate to compete. There isn’t a beverage company, chip company, or distillery at any kind of scale that is working without automation.

C&T Today: Finally, where do you see the future of pre-roll tech heading, and what role do you hope RollPros will play in shaping that future?

KL: Blunts have been on my radar for some time now, so I’m stoked to see our new XXL Blunt Roller units starting to hit the market! After that, I see big opportunities in packaging automation, because there’s still way too much plastic waste in doob tubes. And personally, I’d love to explore cold-cure hash holes!

In a space where “efficiency” often comes at the cost of consumer experience, Kyle Loucks is proving that automation can be both scalable and soulful. By rethinking how joints are rolled, he’s upgrading machinery and elevating an entire category. In Loucks’ world, the future of pre-rolls isn’t mass-produced. It’s master-crafted at scale.